Level measurement and point level detection in the crushed glass, or cullet, silo

Level measurement and point level detection in the crushed glass, or cullet, silo

Silo for crushed glass

Level measurement and point level detection in the crushed glass, or cullet, silo

Process data

Application

Your benefit

Recommended products

VEGAMIP 61

Backup detection with microwave barrier in filling pipe

- Ceramic adapter ensures long service life of instrument

- Simple measurement outside the container

- Simple adjustment without external setup Tools

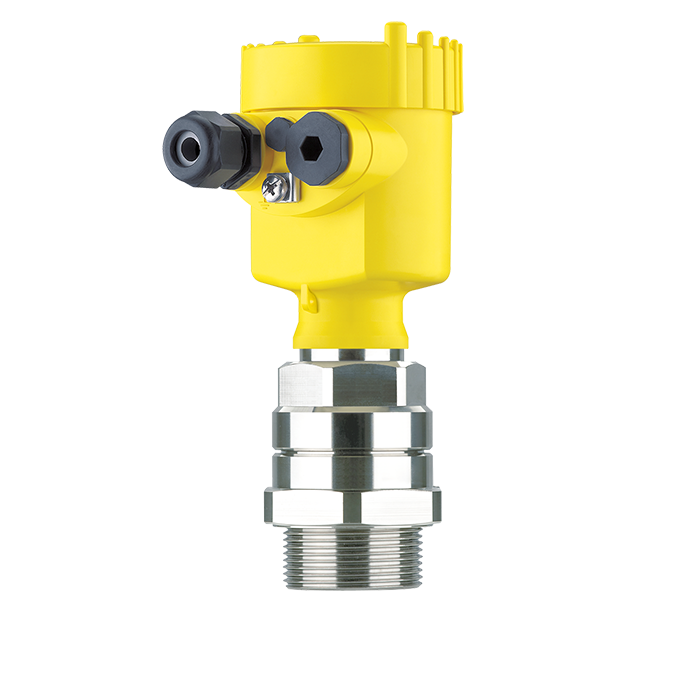

VEGAPULS 69

Level measurement with radar in the cullet silo

- Reliable measurement, even under difficult conditions

- No mechanical wear thanks to non-contact measurement

- Easy mounting and setup thanks to installation from above

Inquiry - Level measurement and point level detection in the crushed glass, or cullet, silo