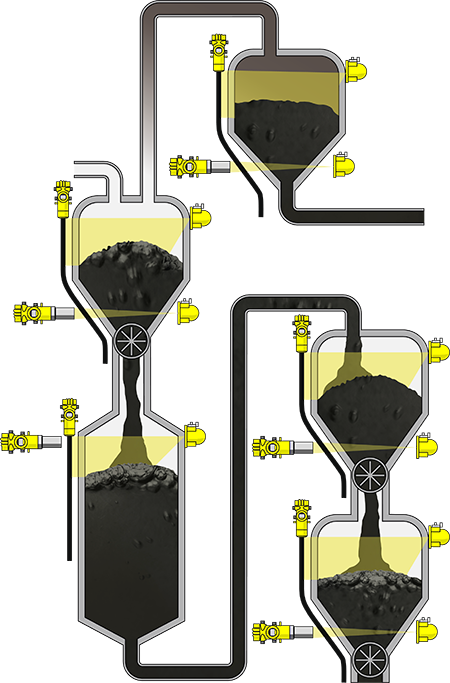

Level measurement and point level detection of catalyst

Continuous catalyst regeneration

Level measurement and point level detection of catalyst

Process data

Application

Your benefit

Recommended products

POINTRAC 31

Radiation-based sensor used as point level switch for catalyst regeneration reactor measurement

- Thanks to lightweight sensor design, no special mounting equipment is required

- Compact and lightweight detector mounts easily

- Secure and reliable level measurement thanks to non-contact measuring technique, ideal for all process conditions

FIBERTRAC 31

Radiation-based sensor for continuous level measurement

- Simple function test during operation reduces down time and resulting costs

- Secure and reliable level measurement thanks to non-contact measuring method

- Long detector length up to 7 m minimizes the need for additional platform construction

Inquiry - Level measurement and point level detection of catalyst