Level measurement and blockage detection in the pulper and conveyor belt monitoring

Level measurement and blockage detection in the pulper and conveyor belt monitoring

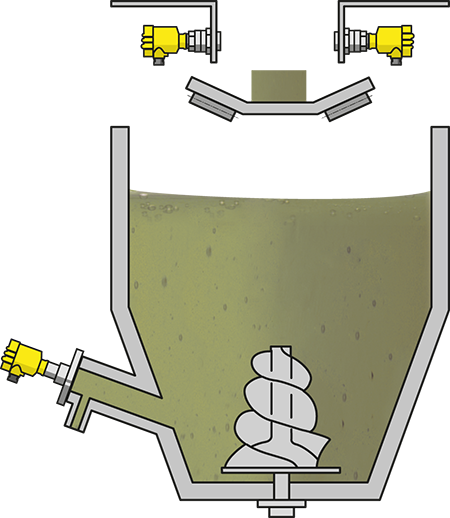

Pulper

Level measurement and blockage detection in the pulper and conveyor belt monitoring

Process data

Application

Your benefit

Recommended products

VEGAMIP 61

Microwave barrier for measurement of the loading height

- Non-contact measurement, therefore wear-free

- Reliable measurement of loading height

- Maintenance-free detection system, no cleaning required

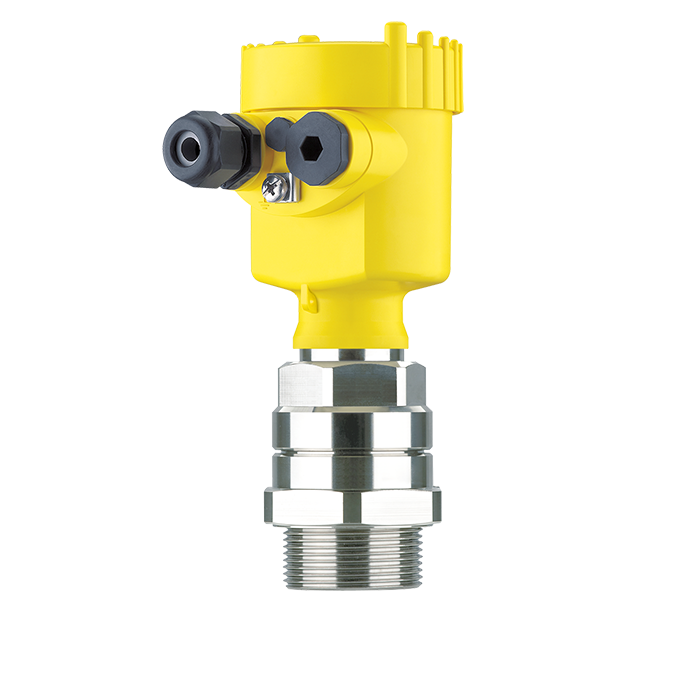

VEGABAR 82

Hydrostatic level measurement in the pulper

- Highly resistant to overload from pressure surges

- Very highly abrasion resistant

- Wear-free ceramic measuring cell for a long service life

Inquiry - Level measurement and blockage detection in the pulper and conveyor belt monitoring