Density measurement in liquor recovery

Pipeline in the liquor recovery process

Density measurement in liquor recovery

Process data

Application

Your benefit

Recommended products

MINITRAC 31

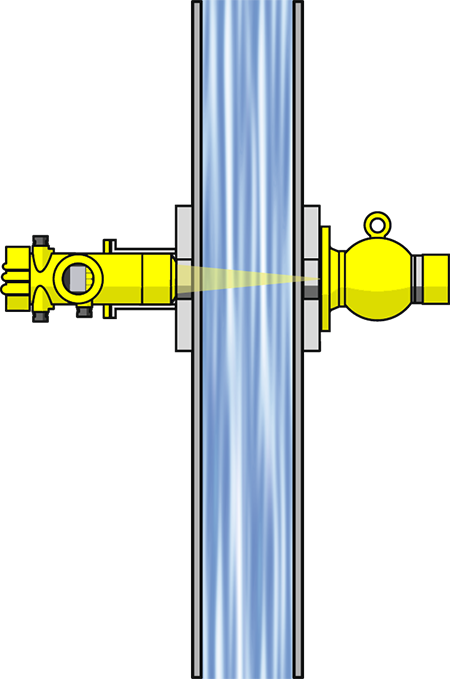

Density measurement with radiation for energy-efficient liquor regeneration

- Enables automation of liquor regeneration process

- Non-contact measurement right through the vessel wall

- Maintenance-free operation

VEGASOURCE 31

The source holder serves as a housing for the radiation capsule and protects it from external influences

- Minimal space requirements and simple mounting

- Operational reliability and safety with pneumatic shutter on the source holder

- Optimum shielding allows use without a restricted access area

Inquiry - Density measurement in liquor recovery