Level and pressure measurement during the mixing of ice cream ingredients

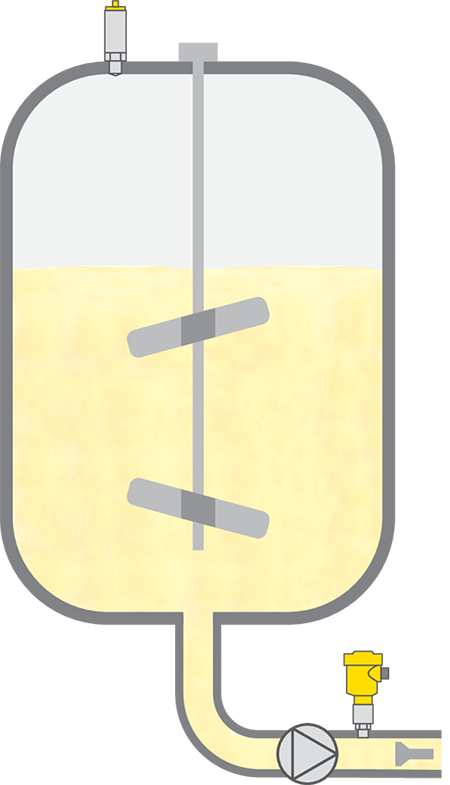

Ice cream ''Premix'' mixer

Level and pressure measurement during the mixing of ice cream ingredients

Process data

Application

Your benefit

Recommended products

VEGAPULS 64

Continuous level measurement with radar in the ''premix''

- Non-contact measurement, unaffected by agitators even in small vessels thanks to extremely tight focusing

- Flange with encapsulated antenna system allows optimal CIP and SIP cleaning

- Reliable measurement, resistant to condensation

VEGABAR 83

Pressure transmitter for monitoring pressure in a homogenizer

- Robust diaphragm easily handles high pressures

- Resistant to vacuum during the cleaning cycle

Inquiry - Level and pressure measurement during the mixing of ice cream ingredients