Level measurement and point level detection in the grain silo

Grain silo

Level measurement and point level detection in the grain silo

Process data

Application

Your benefit

Recommended products

VEGAPULS 69

Radar level measurement in the grain silos for malt production

- Reliable measurement, independent of dusty environment

- High reliability through tight focusing

- Maintenance-free operation through non-contact measuring method

VEGAVIB 63

Vibrating level switch for detection of maximum levels in silos

- High measurement reliability thanks to compact rod design

- Reliable level detection, even with low bulk densities and changing media

- Simple installation near the filling opening

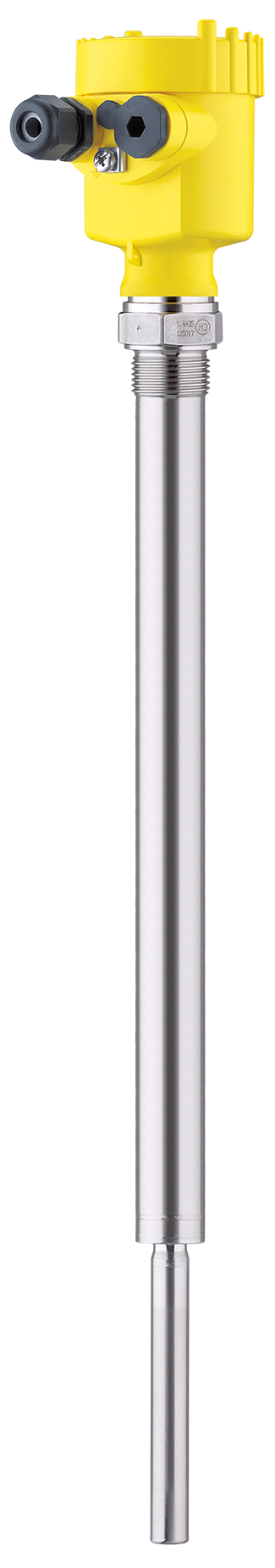

VEGAVIB 61

Vibrating level switch for detection of minimum level to avoid empty silo

- Compact rod design avoids buildup on the sensor

- Simple installation near the discharge opening

- Reliable function through product-independent switching point

Inquiry - Level measurement and point level detection in the grain silo