Point level and pressure measurement in energy production from liquid manure

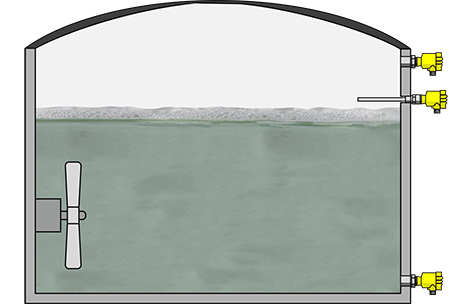

Slurry tanks in biogas plants

Point level and pressure measurement in energy production from liquid manure

Process data

Application

Your benefit

Recommended products

VEGACAP 64

Point level detection with capacitive level switch for full and empty alarm in the slurry tank

- Insensitive to product build up, even under conditions of extreme fouling

- Robust, maintenance-free sensor design

- Adjustment-free setup and commissioning minimizes costs

VEGABAR 82

High-precision pressure measurement in the fermenter

- Different measuring cells allow a targeted application solutions

- High chemical and mechanical resistance thanks to ceramic measuring cell

- Wide array of process fittings ensure easy integration into existing systems

Inquiry - Point level and pressure measurement in energy production from liquid manure