Quantity measurement on the feed belt to the coal mill

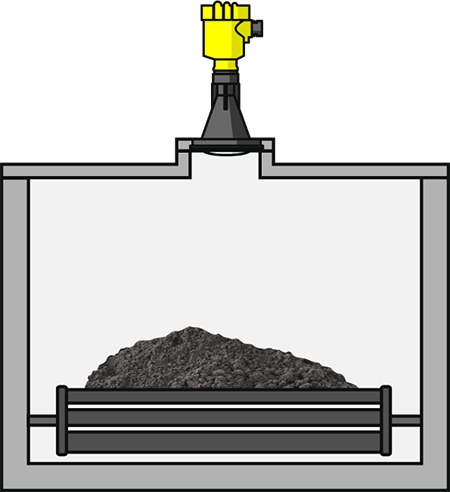

Feed belt to the coal mill

Quantity measurement on the feed belt to the coal mill

|

|

Process data

Application

Your benefit

Recommended Products

VEGAPULS 67

Non-contact level measurement with radar for monitoring the feed belts to the coal mill

- Non-contact, maintenance-free measurement

- Reliable measurement even with small measuring ranges

- High measurement certainty in spite of intense dust generation

- High operational reliability even on high belt speeds

Inquiry - Quantity measurement on the feed belt to the coal mill