Level measurement and point level detection in colour pigment packing

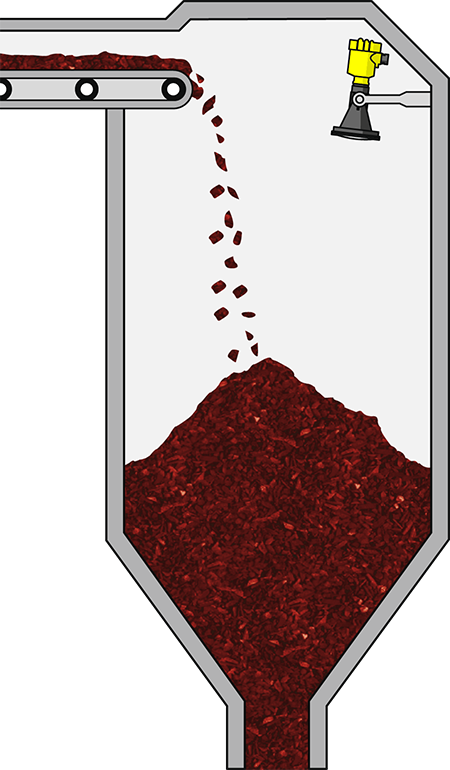

Filling silo for colour pigment

Level measurement and point level detection in colour pigment packing

|

|

Process data

Application

Your benefit

Recommended products

VEGAFLEX 82

Continuous level measurement with guided radar in filling silo

- Accurate measurement despite extremely dusty environment

- Reliable level measurement, even in media with low dielectric constant

- Simple and fast setup with display and adjustment module

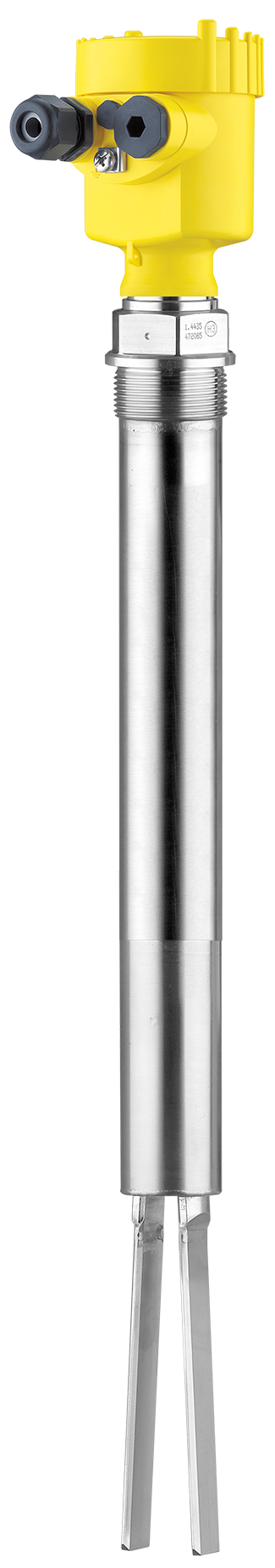

VEGAWAVE 63

Vibrating level switch for protection against overfilling

- Simple setup without calibration

- Reliable detection despite changing density of the medium

- Dependable function thanks to product-independent switching point

Inquiry - Level measurement and point level detection in colour pigment packing